Offer

Spray on chrome & color chrome service

This service involves getting a perfect mirror effect in any color using specialist chemical products & lacquers manufactured purely in laboratory. Technology our company uses is process of combining 7 or 8 layers (depending on the material type), from which every layer is furnace heated in different temperatures for specific period of time. The most important aspect of spray on chrome technology is total acid alkaline intertnes of the coating (layer will not oxidize or oxygenate and is protected against corrosion) and ability to apply it to surfaces made of any material.

List of materials we currently support Spray on Chrome on:

- all types of steel materials,

- casts,

- all types of aluminium and aluminium alloys,

- ZnAl (the most difficult metal to apply chrome on),

- all types of plastics: PP, PE, ABS, HDPM, PP+PE, PP+HDPM, PC, PS, Nylon, Plexiglas, etc,

- glass fibers,

- styrofoam & other foam materials,

- glass, porcelain,

- rubber.

Chemical products & lacquers distribution

We are authorised distributor of chemical products & lacquers required to fulfill spray on chrome technology. All products received from us are top quality and also comply with all necessary standards, and are certified, We achieve this by working directly with laboratories. This allows us to pride ourselves with repeatability of end result with every order. Our company provides full specification for every chemical products we provide.

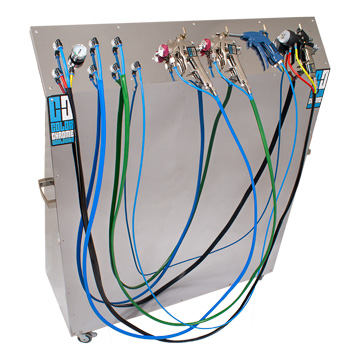

Production and sales of spray on chrome assemblages

Silver Pro-360 plating machine is a device that we have created and production of which happens completely in-house. It is protected under patent in Republic of Poland Patent Office. It is without a doubt the best made assemblage for spray on chrome process ever made in the world. It is made 100% of stainless acid-proof steel. All components within the assemblage are certified and has been checked against chemical resistance.

Characteristics of Silver Pro-360 plating machine:

- highest precision in chemical applications,

- highest precision of adjustment & tuning,

- highest repeatability of chemical reaction,

- lowest consumption rates of chemical products,

- all components are made of stainless acid-proof steel,

- durability & reliability,

- 24 months warranty.

Training

As the only company in Poland, Europe and the world, we have established technical training program divided into 4 stages. Every stage takes 1 working day, and all 4 days of training is completed on customer’s site, who is establishing a partnership with our brand. This is the most convenient and most effective way of teaching this innovative craft, which you can observe by increasing amount of branches and quality we represent.

Our company’s pride is being the first company to publish „Spray on chrome technology fulfillment manual”) by Sojka Investments limited company, owner of Color-Chrome Worldwide brand. Remember, that training is the most important stage of spray on chrome technology implementation process for your company. This unique training program will allow you to gather all necessary information regarding fulfilling our technology.

Training provided covers:

- preparation of a part,

- part renovation and filling,

- anti-corrosion Priming and filling,

- part’s surface polishing,

- lacquer application to silver and it’s protection,

- spray on silvering,

- mixing and applying full spectrum of colors to spray on chrome,

- flat surfaces coloring technology application.

Service

We offer full service of all equipment provided by us. We guarantee all repairs and components replacement carried out under 24 month warranty in Silver Pro-360 plating machine, Silver Pro-720 plating machine and water distillation system H2O Q4. that are found malfunctioning. We also offer out of warranty service. We stock all replacement parts. This guarantees shortest time for parts replacement, maximum of 72hrs.

Flat surfaces coloring

Once again, we are the only company in the world to own this innovative and totally unique flat surfaces coloring technology. This process consists of applying specialistic bonding primer to smooth part (list further down) and applying dedicated colorless lacquer with specialistic dyes. End result is a mirror in any rainbow color. This process shows very high physical damage resistance and no possibility of coloring coating dissection from smooth surface of the part. Technology is protected under patent application in Republic of Poland Patent Office.

Coloring of flat surfaces can be applied to:

- any galvanic chrome parts, made of any material,

- polished up or brushed stainless steel,

- glass and porcelain.

Example: customer delivers a part that has galvanic chrome in silver applied to it. Thanks to this technology we can change color to copper (for example) without loosing mirror effect or structure of the material, without using copper itself. Thanks to that we can achieve copper galvanic chrome, that can be nurtured like a car paint.